Climate Friday | Building over Brighton’s aquarium: precision engineering that balances heritage, complexity and carbon

11 July 2025

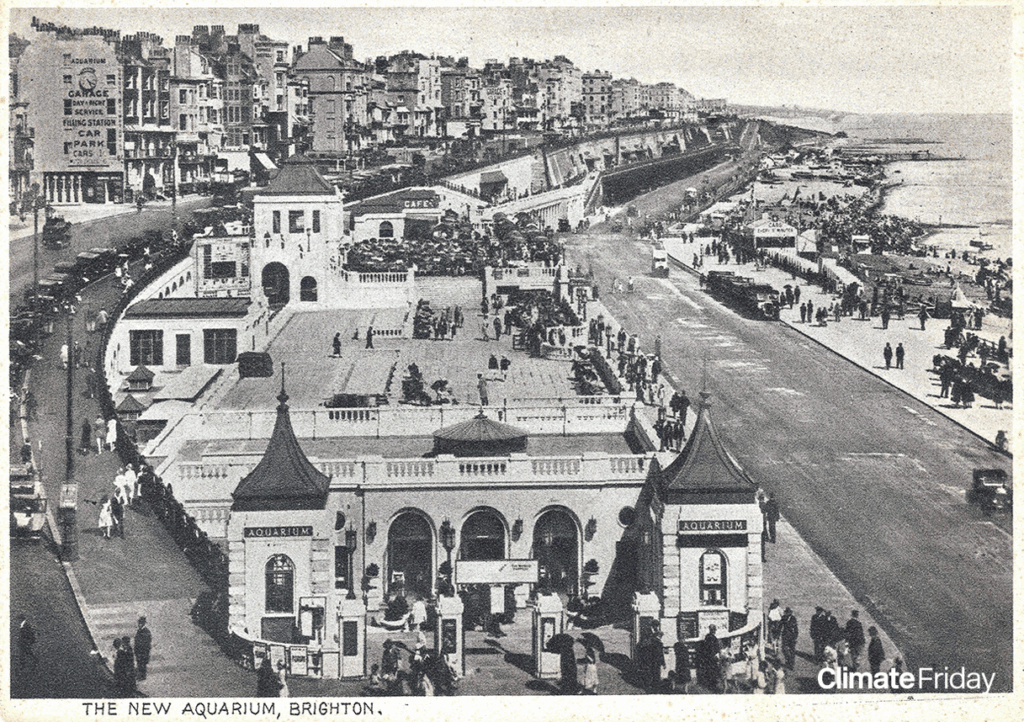

A Living Landmark

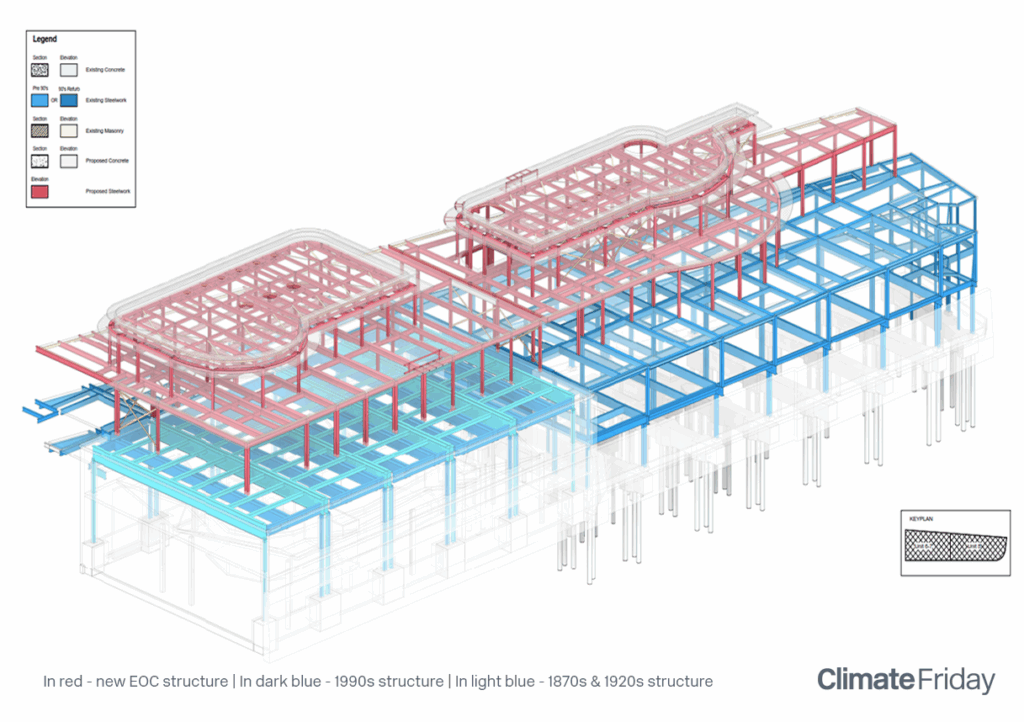

Conceived and designed by renowned engineer Eugenius Birch, the Brighton Aquarium opened in 1872 and is still today the oldest operational aquarium in the world. Over the decades, it has undergone several major adaptations, from a double-height subterranean concert hall added in 1929 used as a nightclub in the 1950s, to a major intervention adding a dolphinarium in the 1960s, later converted into a shark tank in the 1990’s.

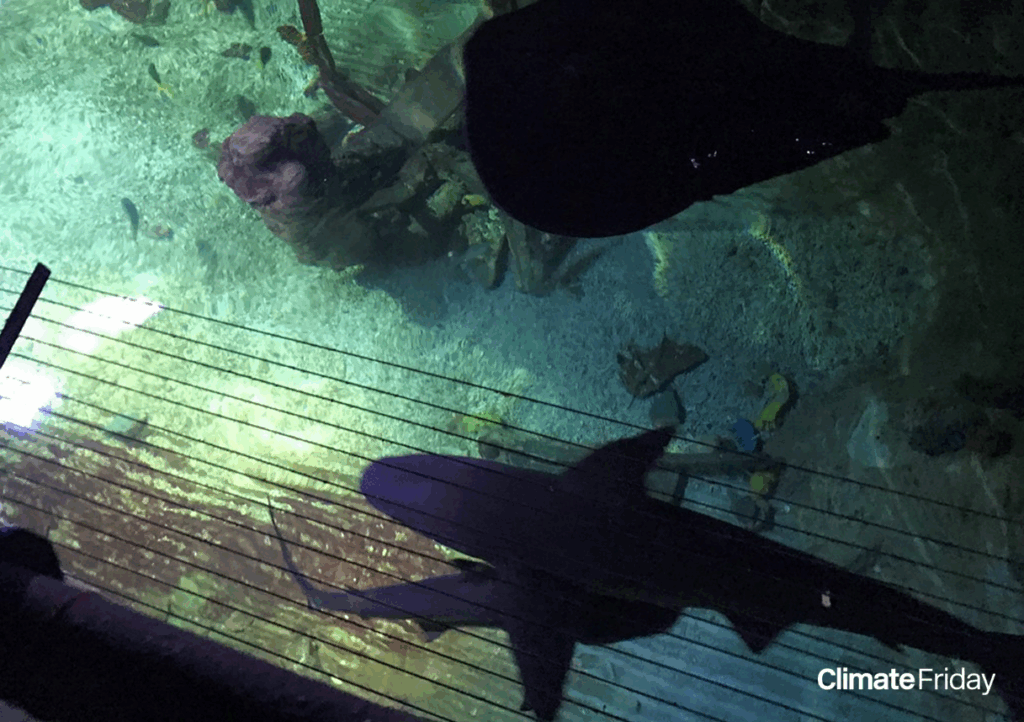

The Grade II listed structure showcases a layered combination of ‘clay pot’ and precast floors, both cast/wrought iron, loadbearing masonry and modern steelwork added at various points along its history. The shark tank, which still exists today, sits on a concrete raft slab that is cleverly isolated from the original shallow foundations and masonry piers.

The Extension: Our Involvement

The vertical extension created two new floors in place of some unloved single-storey retail units which were never leased in over 20 years. The scheme introduced a diverse mix of restaurants, bars, workspaces, a gym, swimming pool, and rooftop terraces.

We designed the new floor levels using a braced primary steel frame supporting lightweight metal joist cassette floors with OSB timber decking and a proprietary roof deck to support the green roofs. The resulting floor and roof systems were as lightweight as practically achievable, with total build-up weighs under 100 kg/m². All of this was constructed above the Sea Life Centre, which apart from a 6-week shutdown for some redecoration, remained fully operational throughout, a logistical achievement considering the presence of tenants and marine life beneath!

Engineering for Complexity

Our structural feasibility study in 2015 revealed that the massing of the proposed extension to be technically possible, but only just! This tight margin defined the project’s core design challenge: the new structure needed to be lightweight to avoid overloading the historic buildings frame and foundations. This constraint shaped the entire design process and demanded a stringent approach in every sense, driving innovation in structure, construction logistics and materials.

Load Capacity Limitations & Occupancy Load Assessments

Following the feasibility work, we undertook further investigations to better comprehend the history and the existing structure’s behaviour, intricacies and impacts of previous interventions. We were fortunate enough to obtain a thorough set of archived historic drawings for the project. Piece-by-piece with on-site verification, we were able to build up a full picture of the frame and its bolted connections, allowing a robust analytical assessment of the building. The challenge was further complicated by planning conditions released in 2016 proposing a heavy biodiverse roof to enhance the site’s ecological value. However, this was not achievable due to weight restrictions, we advised the design team to consider a lighter-weight solution, such as sedum lawn, to meet both structural constraints and environmental goals. This careful balancing act was extended to every aspect of the new build. Each layer, from facades to finishes, was scrutinised to ensure weight remained within allowable limits.

The limited capacity of the historic structural also prompted us to perform a granular crowd loading study. This demonstrated that with a managed tenancy, different areas of the building could be used safely under controlled conditions. As a result, lower occupancy assumptions reduced design live loads, and in turn, steel tonnage, strengthening requirements, and foundation loads.

Vibration

With such long spans and low self-weight, vibration became a critical design consideration. We carried out a parametric footfall analyses varying floor depth, column spacing and grid layout to achieve the optimum configuration that would mitigate vibration and ensure occupant comfort. To allow for late-stage adjustments, we integrated column stubs into the primary frame as a precaution. Alternatives such as sprung floors and electronic dampening systems were explored but ultimately discounted, as the client wanted to maximise ceiling heights within the planning envelope.

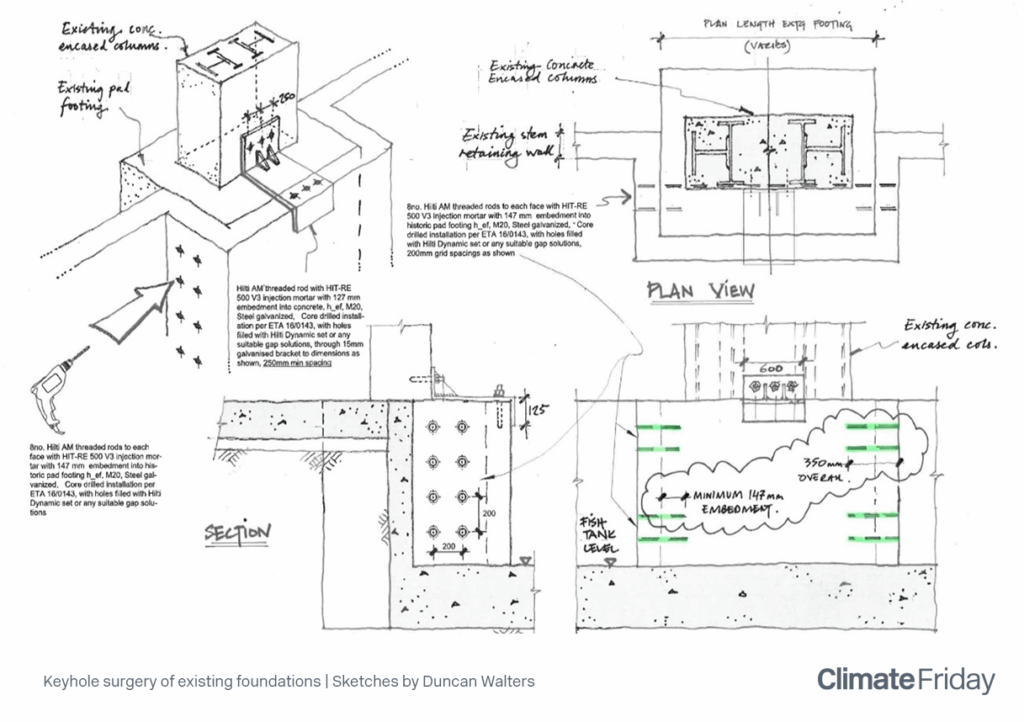

Re-use of Foundations

Perhaps the most delicate intervention was below ground. Accessing the foundations beneath the Sea Life Centre was extremely constrained, both spatially and in time, due to the aquarium’s own refurbishment works. To overcome this, we engineered a form of “keyhole surgery” on the foundations: creating shear links between the original 19th century pad foundations and the mid-20th-century raft slab. This enabled loads to be redistributed across a wider area of the chalk stratum, improving the structural capacity of the foundations without major intrusive works.

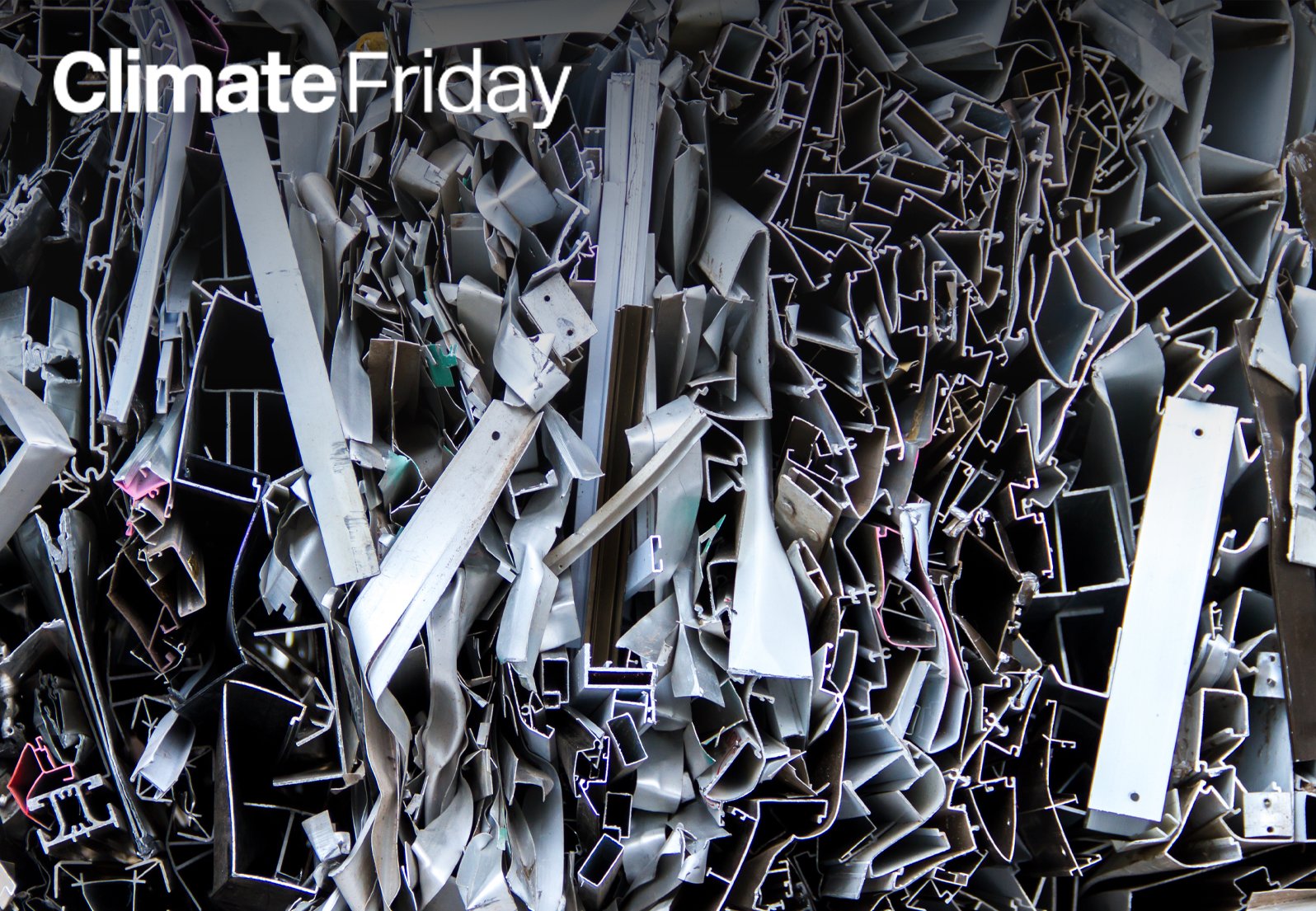

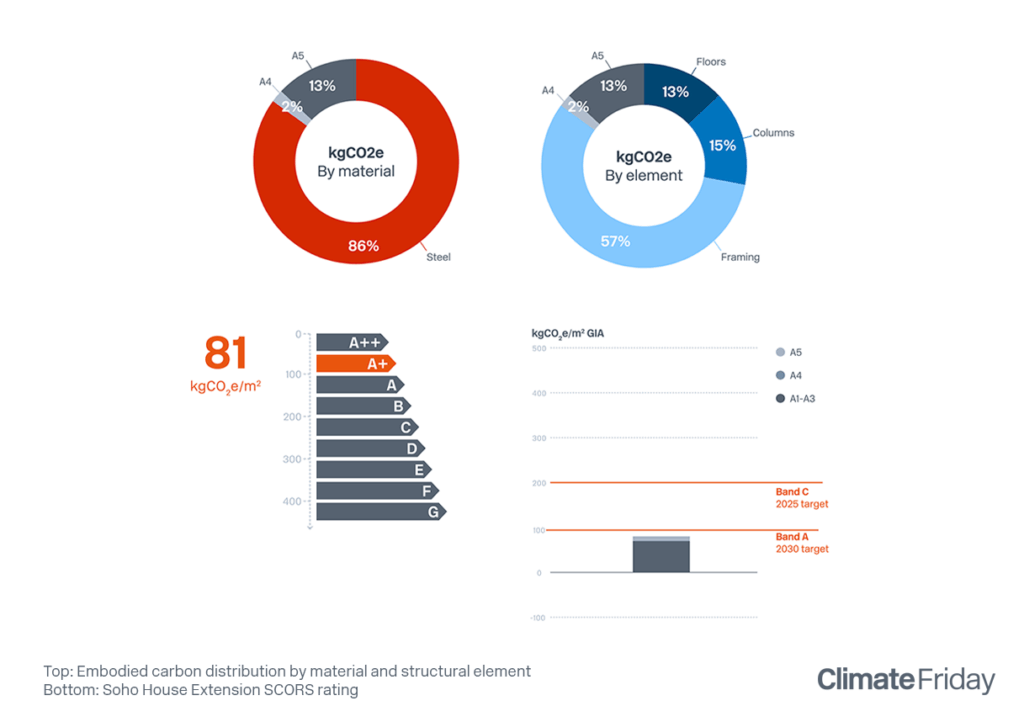

A Low-Carbon Legacy

Through strategic reuse, minimal intervention, and careful load management, the project delivered more than just architectural ambition, it achieved an inherently low-carbon outcome. By avoiding geotechnical works, retaining the existing structure, and optimising every new element for weight and efficiency, the team significantly reduced material demand and embodied carbon, achieving an A+ SCORS rating.

The result is a bold and functional addition that respects its historic host and demonstrates how a highly constrained site paired with engineering ingenuity can shape sustainable outcomes. As we look toward the future of retrofit and reuse, projects like this raise an important question: what if constraint isn’t a limitation, but a catalyst for better design?

Written by Duncan Walters

Client: The Vinyl Factory

Architect: Michaelis Boyd Architects