Climate Friday | Disassembly by Design: Mapping Facade Design for Component Reuse

22 August 2025

With the climate crisis unfolding, and the construction industry only reusing 1% of materials from demolition (CircoTrade, 2024), it is as relevant as ever to consider ways to reduce our impact through the services we provide.

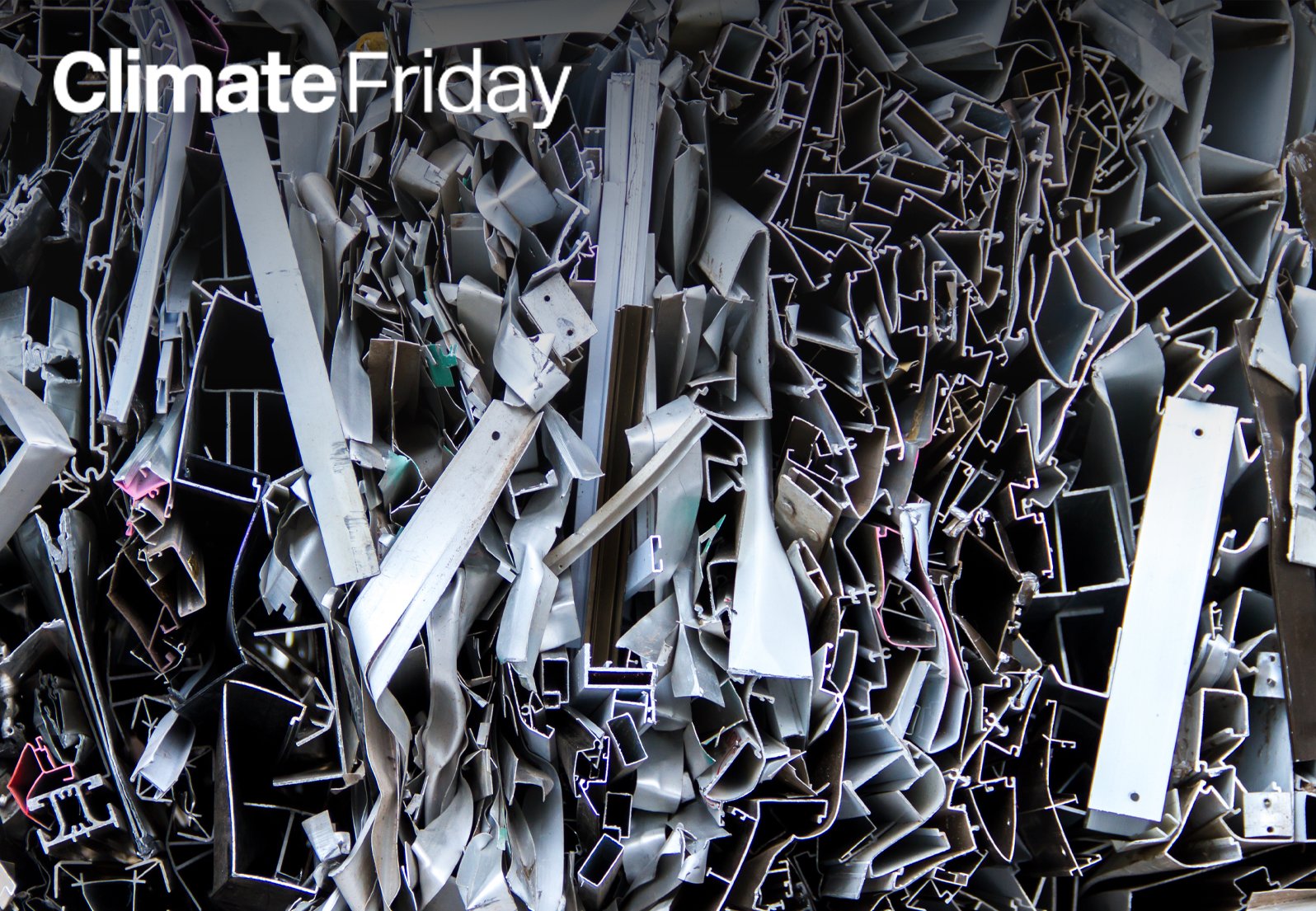

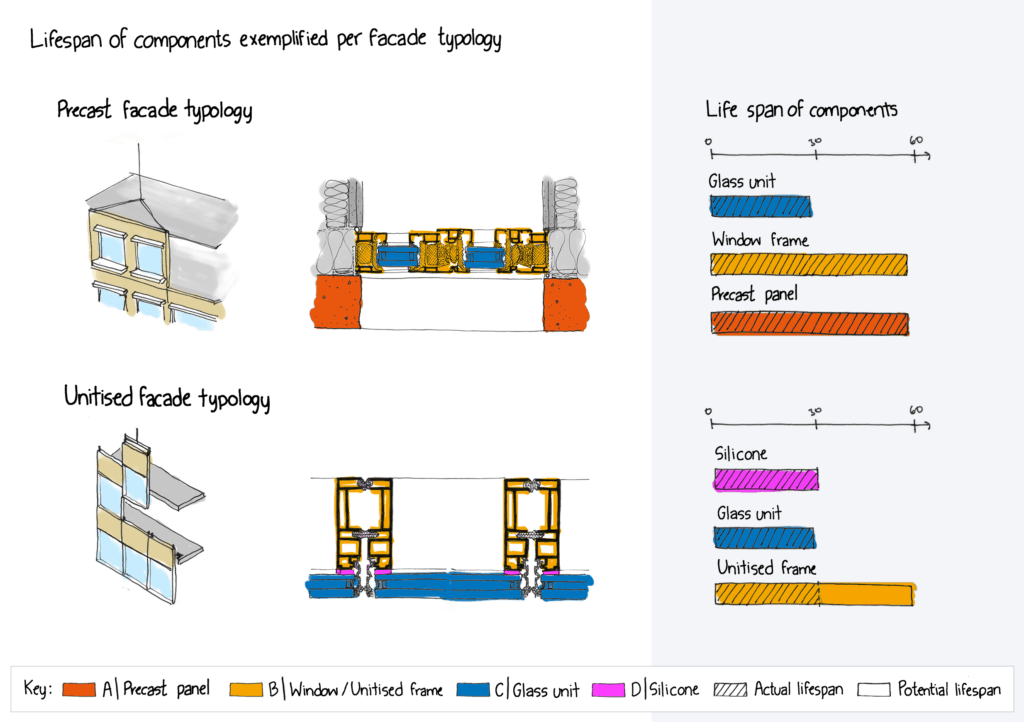

The facade of a building is one of the most material intensive portions, accountings for 10-20% of the building’s embodied carbon footprint over its whole life cycle (2050 materials, 2025). In recent years, the industry has made measurable progress in defining pathways for recycling, most of which rely on shredding materials into secondary feedstock. While the route to recycling is now familiar; the route to facade disassembly for component reuse remains mostly unexplored. However, interest for reversible construction practices is accelerating in the field, driving contractors to explore what was once considered niche; designing facades not just for assembly, but for future recovery.

The Paradox

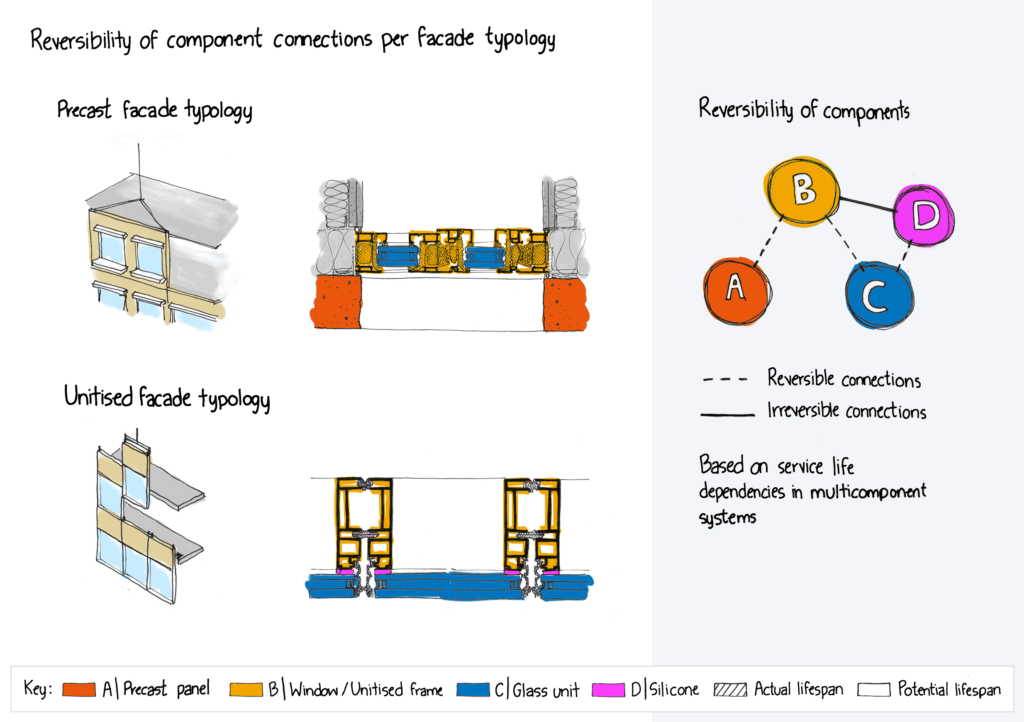

An ideal facade would last as long as the building itself, but this is not possible for all facade materials. For example, precast panels and stone can typically meet a 60-year building lifespan, while glass, gaskets, and silicone seals degrade and require replacement after about 30 years. Window and curtain wall frames, most commonly made from aluminium, in theory have the capacity to last as long as the building. In practice though, detailing methods and the bonds between elements with dissimilar lifespans, such as frames with glazing and gaskets, often lead to premature discarding of the aluminium frames. Essentially this means that even if the original design and dimensions remain unchanged, old frames will be disposed of, recycled at best, and new frames will be produced, through the carbon intensive process of aluminium production. Therefore, it is essential to gain a better understanding of the main logistical and technical challenges that prevent material reuse in the industry.

Logistical Challenges

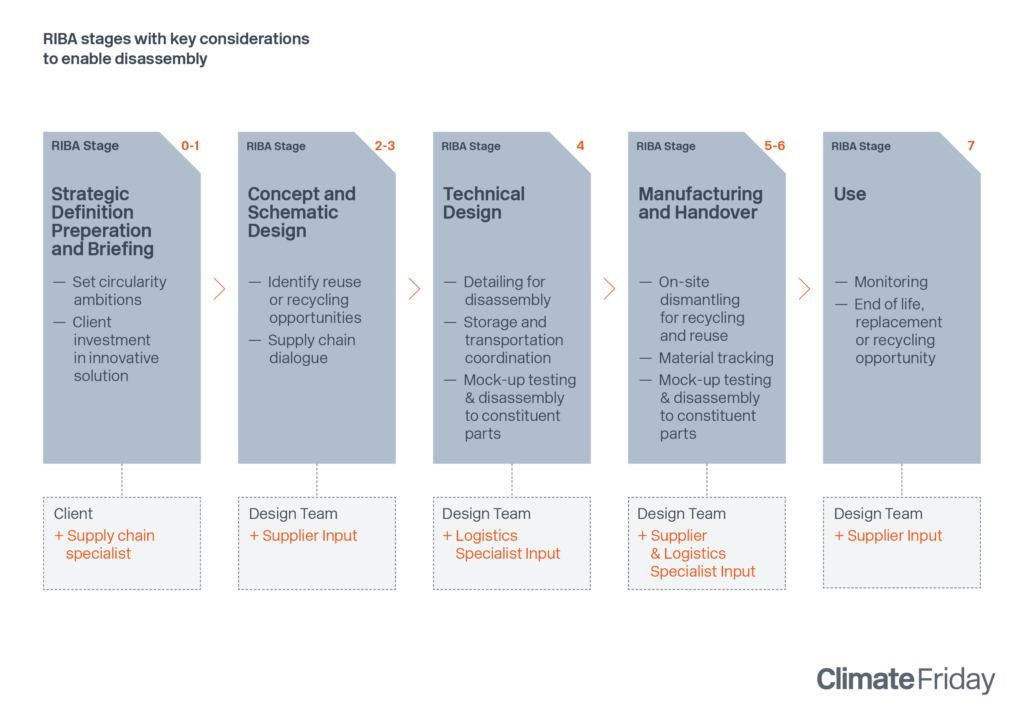

Careful deconstruction of a facade is not yet regulated and occurs only under early coordination with explicit guidance documents that only facade contractors or material processors, like Schüco, Wicona, or Saint-Gobain, can offer to demolition contractors. Considering how complex this coordination currently is, early communication seems to be necessary; allowing clients, designers, and specialists to align the project specific circular ambitions and embed dismantling logic into the design from the very start. This hints at the potential need for a new stakeholder; specialised dismantling contractors focused on material preservation rather than speedy demolition. The introduction of this specialist could facilitate the disassembly process, practically by focusing their skills on component recovery and, logistically by bringing together all the relevant parties that now need to individually approach the client.

Apart from the communication challenges, space management is also critical. On-site material separation is crucial to prevent contamination and improve recycling or reuse quality, yet this requires time, organisation, and storage space. Depending on the material, the dismantling and storage process varies. As confirmed by the market, glass is usually separated from the frames and shattered on-site to facilitate transportation, while frames and sub-assemblies often travel intact, requiring more space. If the quantities removed from site are not large enough, waste management partners such as KHP, ERITH, Power Day, and John F. Hunt will store material until they reach critical mass, before sending it to processing, thus highlighting the need for regularly available storage space, where recovered materials can be temporarily kept.

With the current industry set-up, if demolition contractors arrive first, the risk of premature downcycling looms large with materials likely being sold to the highest bidder, effectively locking valuable resources into a low-value downcycling rather closed loop recycling or reuse. If resolved, the identified market gaps stated above, could encourage consideration of dismantling for more projects.

Technical Challenges

At a detail level, the technical challenges of disassembly are embedded in the very systems designed for permanence. Facade assemblies frequently rely on details like corner cleats or silicone bonded fixings and interfaces, elements optimised for stability, not reversibility. To allow for reversible solutions, systems either need to change their fundamental connection design, or the very practices now perceived as irreversible shall be examined and challenged. On the former, the industry has been developing alternatives, such as square-cut and screw connections (as Schüco suggests) or the reversible stick system mullion-transom connections (Jansen’s VISS system), although these solutions still result in specific visuals, often clashing with architectural preferences. For the latter, with silicone being a common denominator of most challenging interfaces, reconsidering the permanence of the material bond and exploring methods for its reversal after curing may offer a viable path forward.

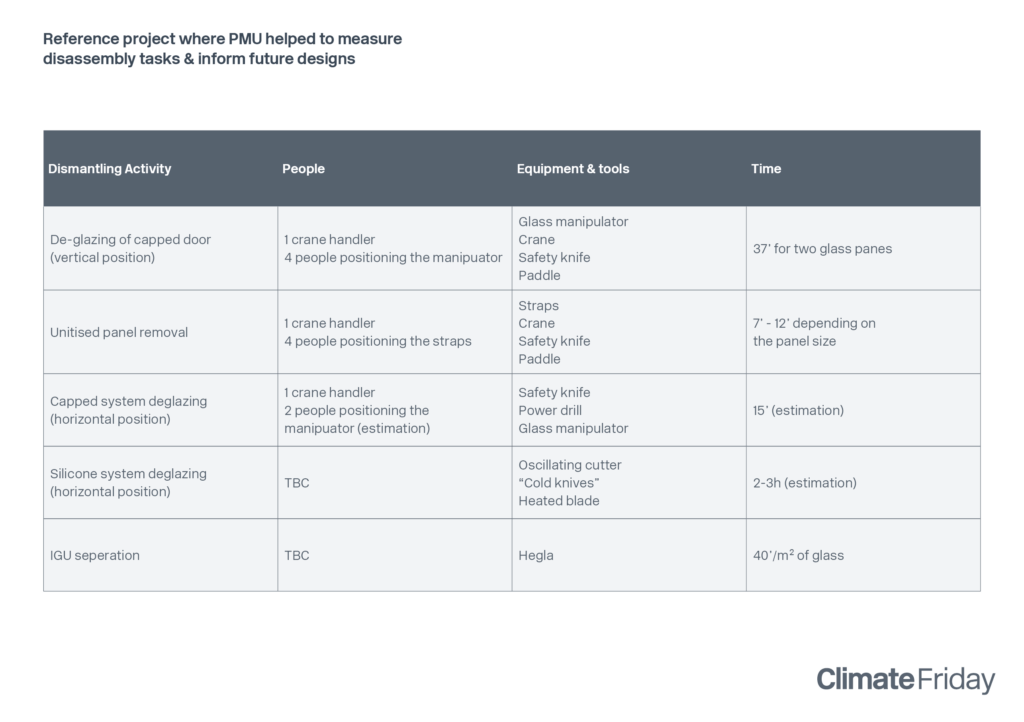

Although PMU (Performance Mock-Up) components cannot be reused under current regulations, they do provide an opportunity to experiment with dismantling methods and assess resource requirements, from specialised tools to skilled labor. While experience has shown that disassembly typically takes longer than assembly, it is important to quantify exact data, allowing us to evaluate the true impact of careful dismantling. We at Eckersley O’Callaghan, along with other industry bodies, are calling for such records to become standard practice, as it helps map the hidden complexity of reuse-ready facades.

Conclusion

The journey toward dismantlable facades is not purely a technical problem: it is cultural, logistical, and contractual. Current industry practices still lean heavily on recycling as the main sustainability strategy, but opportunity lies in rethinking the processes earlier in the chain. Clients play a decisive role: without their willingness to prioritise circularity from the earliest stages, dismantling remains an afterthought rather than a design driver. PMU’s, which are often treated as expendable prototypes, could become learning laboratories, controlled environments where contractors rehearse disassembly and identify resource needs before systems are deployed at scale. Yet, technical refinements alone will not suffice. Logistical adaptation, including coordinating specialist roles, allocating space, and sequencing dismantling alongside other trades, is just as critical. Above all, careful disassembly requires time, care, and planning, commodities that demolition-driven workflows rarely allow. If the industry is committed to breaking the cycle of premature replacement, dismantling shall be considered already at project inception. Only then does reuse shift from an aspiration to a viable, systemic practice.

Co-written by Javier Montemayor & Maria Dimas.

Bibliography

CircoTrade. (2024, August 29). Retrieved from ‘Futures trading: A way to scale-up the re-use of building materials’.

2050 materials. (2025, July). 2050 materials. Retrieved from ‘Using facade design to reduce embodied carbon’.

World GBC. (2025). WorldGBC. Retrieved from ‘Bringing embodied carbon upfront’.

At Eckersley O’Callaghan, we are committed to progress, applying our expertise, and collaborating with those who share our values to accelerate change in our industry. Learn more about our commitment to sustainability here.