Climate Friday | The true cost of your building

13 July 2021

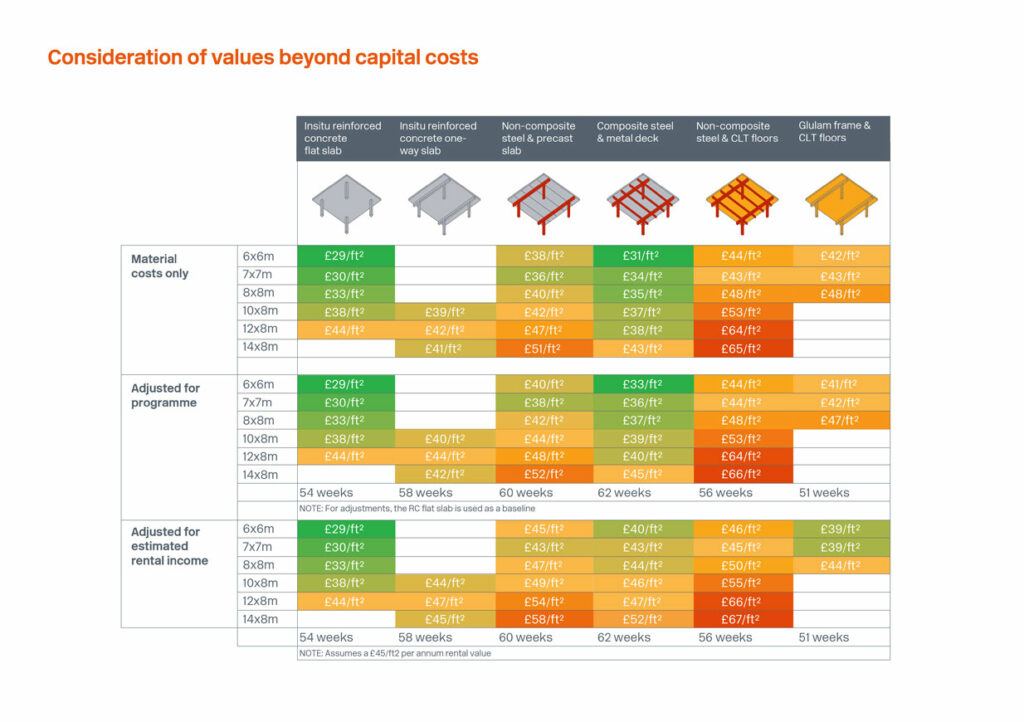

Added on 09.12.2022 – We have retrospectively followed up on the original case study by trying to consider how much it would actually cost to build out each of these schemes. We engaged the generous professional input provided by Avison Young and Exigere Ltd to gauge the influence of construction programme and material supply chain costs to extract a fuller understanding of material choices and speed of construction. The below chart shows the overall cost per square foot against each construction typology and grid size when considering programme and time to market, even attempting to look beyond practical completion and getting towards ROI. These figures only give a snapshot in time, which constantly needs updating to reflect a volatile market, however it is evident that with so many levers at play there is all the more reason to complete in depth assessments at the outset of a project.

Embodied carbon is the new currency of a building. In our latest Climate Friday piece Director Duncan Walters and Project Engineer Ieuan Marks-Venables explain how their latest piece of embodied carbon research fits into the wider sustainability picture.

Office floor plates may seem pretty standard in their design, but when it comes to embodied carbon (EC) we’re analysing every part of a building’s superstructure to ensure we’re armed with the right information to make the most sustainable choice.

This is why.

According to the London Energy Transformation Initiative (LETI) design guide, a building’s superstructure accounts for around 48% of the total embodied carbon in a new commercial office. The decisions we make as engineers at concept stage, can have vast implications on a building’s overall emissions.

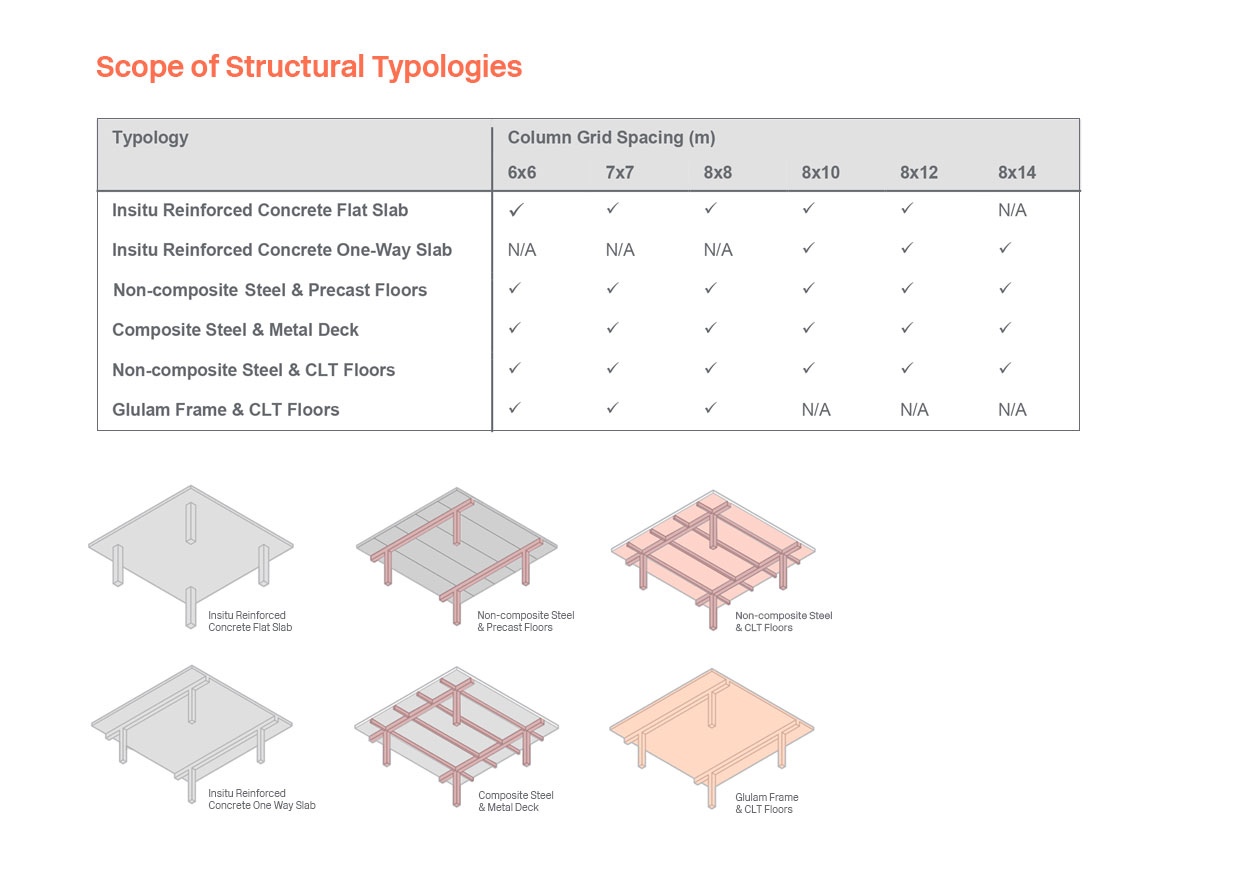

By considering different materials and their suitability for various structural frame types and columns grid spacings we have homed in on the most carbon efficient layouts to allow our clients to make informed choices. By publishing this data, we hope to continue do our part in bringing the industry up to a unified sustainability standard.

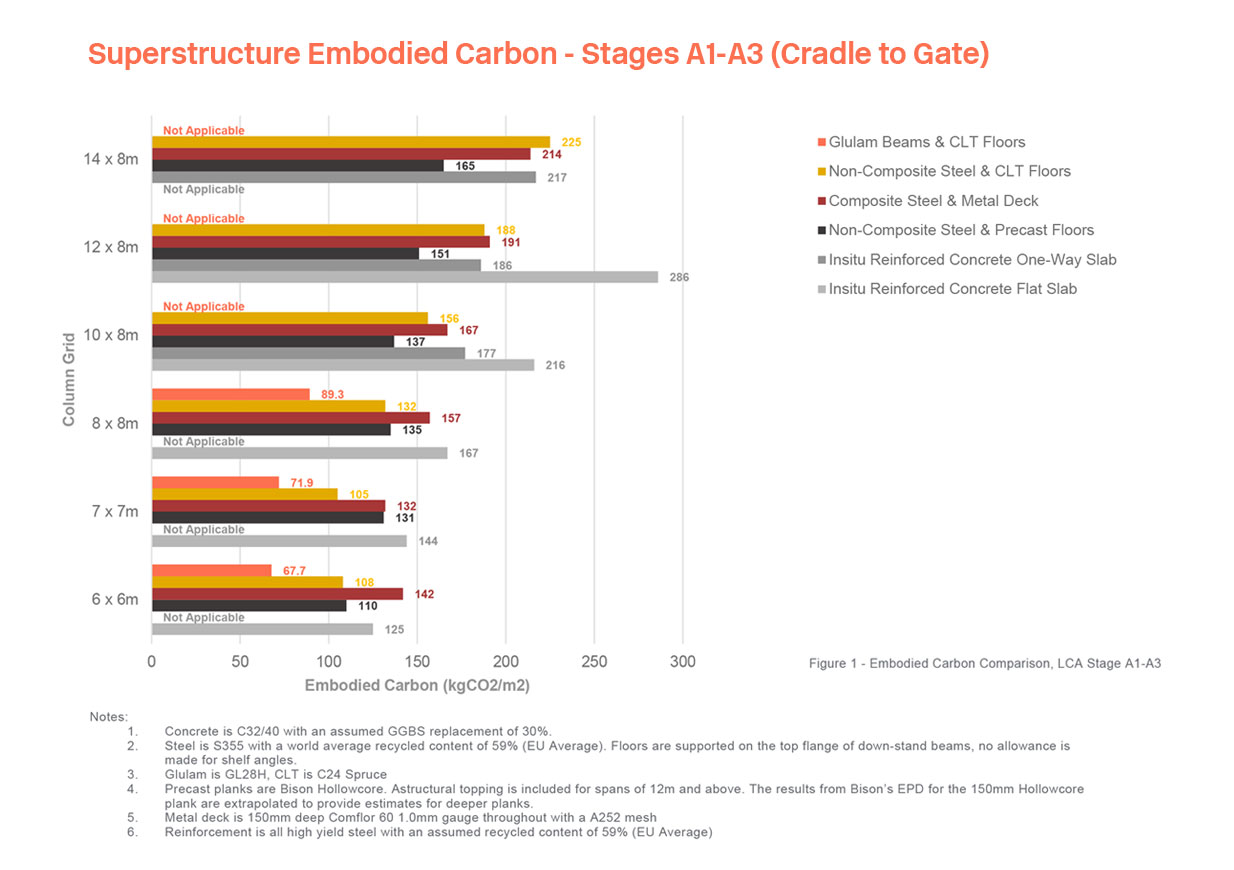

Our findings can be summarised as below:

- As a general rule, a tighter column grid will provide reduced embodied carbon emissions.

- Glulam and cross laminated timber (CLT) frames are clearly preferable in EC terms up to a grid size of 8m x 8m, beyond which, beam sizes become excessively large to control serviceability requirements.

- A hybrid solution of CLT floors and steel can provide improvements on a typical steel or concrete frame up to a grid size of 10m x 8m. Beyond this, a steel and precast plank option begins to become a more efficient solution.

- Steel and precast floors are generally lower in embodied carbon than a steel and insitu concrete on metal deck alternative, despite the composite efficiencies in steel design provided secondary beams can be avoided.

- Insitu flat slab construction is a poor EC performer on grids above 7m x 7m. One way spanning concrete systems with downstand beams used far less these days offer better emissions than steel framing options.

We realise that embodied carbon is just one of the many considerations we must account for during the early stages of design. And the structural type chosen will have an impact the building’s cost, height, façade system and operational carbon emissions, amongst numerous other factors. But our results clearly show how we can make large strides to reducing our embodied carbon emissions by choosing the most suitable structural systems.

Notes and assumptions – the small print

The study is based upon a upon an example 5-storey commercial office building over a fixed footprint. The structural design for each option has been carried out to a standardised set of design criteria, accounting for strength, serviceability, fire, acoustics and durability. The results were then inputted into our Embodied Carbon Calculator, which is based on values from the ICE database and specific product EPCs to provide range of data for comparison.

We consider Stages A1-A3 (Cradle-to-gate) of the Life Cycle Analysis, which is defined as the embodied carbon emissions required to extract a raw material and process it to the point it is ready to leave the factory gates for a construction site.

We also do not consider any carbon stored in Timber products. At early design stages we are typically unable to confirm how the structure will be decommissioned at end of life and whether this sequestered carbon will be released back into the environment. The sequestered values are not present here, but offer significant advantages for projects where the longevity or end of life is known.