Contributing to a Sustainable Net Zero London By 2030

28 June 2022

Project Engineer Lukas Ziak explains how at Eckersley O’Callaghan we managed to address carbon reduction through refurbishment on our recently completed London Road Building project for London South Bank University.

As engineers our designs can have the greatest impact on embodied carbon and one key method of reducing carbon and meeting Net Zero targets can be realised through the adaptive re-use of existing structures.

London Road Building is a refurbishment and extension project of an existing four-storey Reinforced Concrete (RC) frame building from the 1970’s with an overall internal area of 20,000m2. The new design houses the campus’ Student Hub and includes lecture theatres, library, study spaces, sports facilities and catering areas; it is part of a wider London South Bank University campus redevelopment.

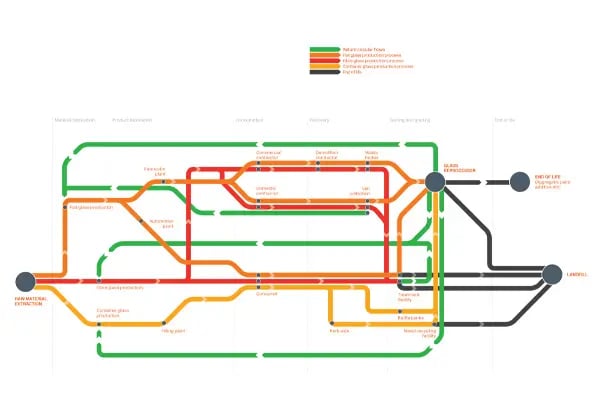

The project demonstrates how an existing building can be upgraded, extending its design life by another 50 years and achieving a contemporary look, while minimizing the carbon footprint of construction. The project is a showcase of the concepts we need to apply to each building (in this order): ‘Building nothing – Build less – Build clever – Build efficient – Minimise waste – Build low carbon’.

London Road Building refurbishment is the largest carbon fibre strengthening application carried out in a building in the UK to date. The original design hindered the effort to reuse the building as it was significantly optimised, without much spare structural capacity within the beams and the waffle slabs. Justification of existing RC elements (beams, slabs, walls, columns, and foundations) under new loading and / or strengthening designs was the main structural engineering challenge.

A comprehensive review of the reinforcement details from available archive information, together with a holistic assessment of the building’s stability and existing concrete conditions allowed us to confirm that the decision of retaining and repurposing the existing structure was viable.

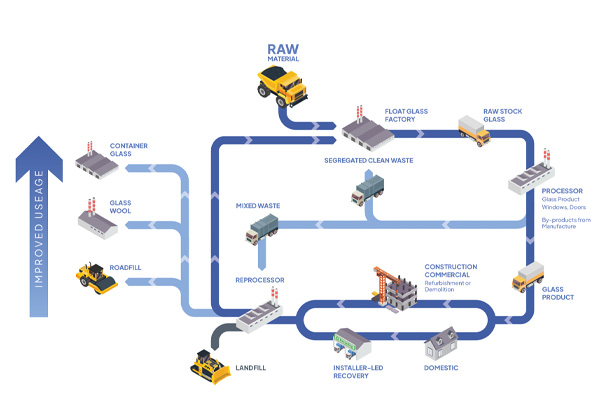

Alterations and new loading conditions were mainly resolved by strengthening the RC beams and slabs using plates, wraps and strips of carbon fibre, for flexural and shear strengthening. This approach fully utilises the existing RC elements and enhances their capacity and strength – as opposed to other traditional methods with extensive steelwork re-supporting the original structure and often taking the existing elements’ capacity out of the equation.

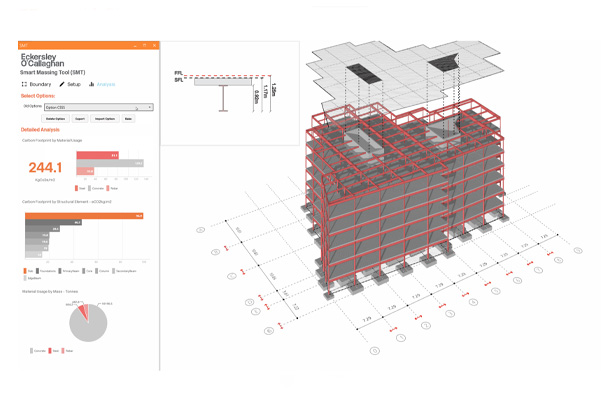

By refurbishing and saving as much of the existing materials as possible, the cradle to gate embodied carbon component related to substructure and superstructure for the project is just 49 kgCO2e/m2. This value can be compared to the approximate structural components of LETI targets – about three and a half times less than the 179 kgCO2e/m2 2020 LETI target and just under a half that of the 105 kgCO2e/m2 2030 LETI target for education buildings.