Climate Friday | Reuse of existing glass

20 August 2021

The sixth assessment report by the IPCC has been a timely reminder of the need for urgent action on climate change, particularly with COP26 rapidly approaching this November.

While much focus has been quite rightly placed on curbing our carbon emissions, we are glad to see that humanity’s wider impact on natural resources and habitats is increasingly part of the debate. The article ‘Addressing the biodiversity emergency’ published in the August edition of The Structural Engineer is evidence of this and provides an indispensable toolkit for how we as engineers can lead on these issues.

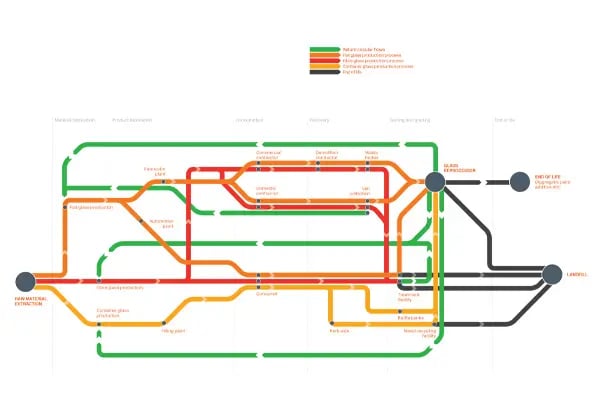

In our previous Climate Friday article on glass recycling, we illustrated the challenges faced in the glass industry to transition to a cradle-to-cradle approach. Francesca Rossi is a Senior Engineer, leading our research on the Circular Economy of Facades. Here, she looks at the possibilities for reuse of glass beyond recycling. What would it take to reuse glass panels taken from existing buildings, while maintaining quality, certification and obtaining warranties from suppliers?

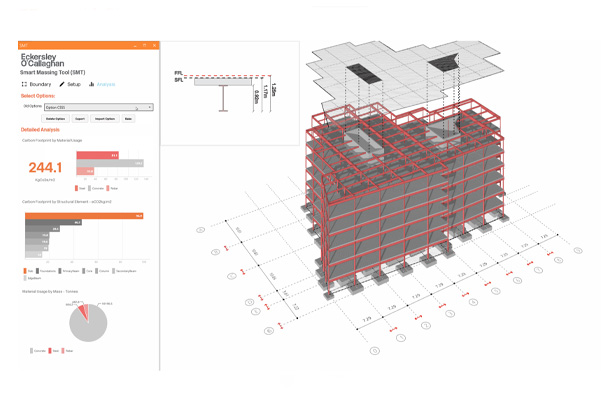

At Eckersley O’callaghan we have embraced this challenge! We are currently working on a refurbishment project in the Netherlands, with an ambitious client who is prepared to provoke the industry towards implementing a circular approach to building materials, particularly glass. In response, we are collaborating with the glass industry and other partners, examining which limitations need to be overcome, but more importantly the opportunities to make this transition happen.

Across Europe, marketplaces for second-hand glass are already emerging. They operate with a network of collection points and sorting facilities that then allow glass manufacturers and processors to buy ‘waste’ product for new applications, or recycled cullets to re-enter the float line. We believe these markets can provide a source of reusable glass stock as it is removed from existing buildings.

We have been mapping out the different stakeholders that would be involved to take ownership of a reconditioned product. The necessary first step is to inspect the glass, any documentation it comes with (such as CE certification) and analyse a specimen to check its quality (for example, oxidation and haze on the surface). The more information available on the glass, the easier it is for processors to assess its potential reuse. We are confident that by taking the right preparatory measures – such as surface polishing – a new IGU or vacuum insulated glass unit can then be created from existing material.

We want the successful reuse of existing glass to become an inspiration to others, working towards the transition to a circular economy. By professionally engaging with second-hand markets in a way that existing products can be certified and guaranteed in line with virgin materials, we believe reuse will become more accepted and replicated widely. We are very pleased to be working with such a forward-looking client, taking up the gauntlet and setting a cutting-edge example to move the whole industry forward.